How Would You Explain the Difference Between Soldering and Brazing

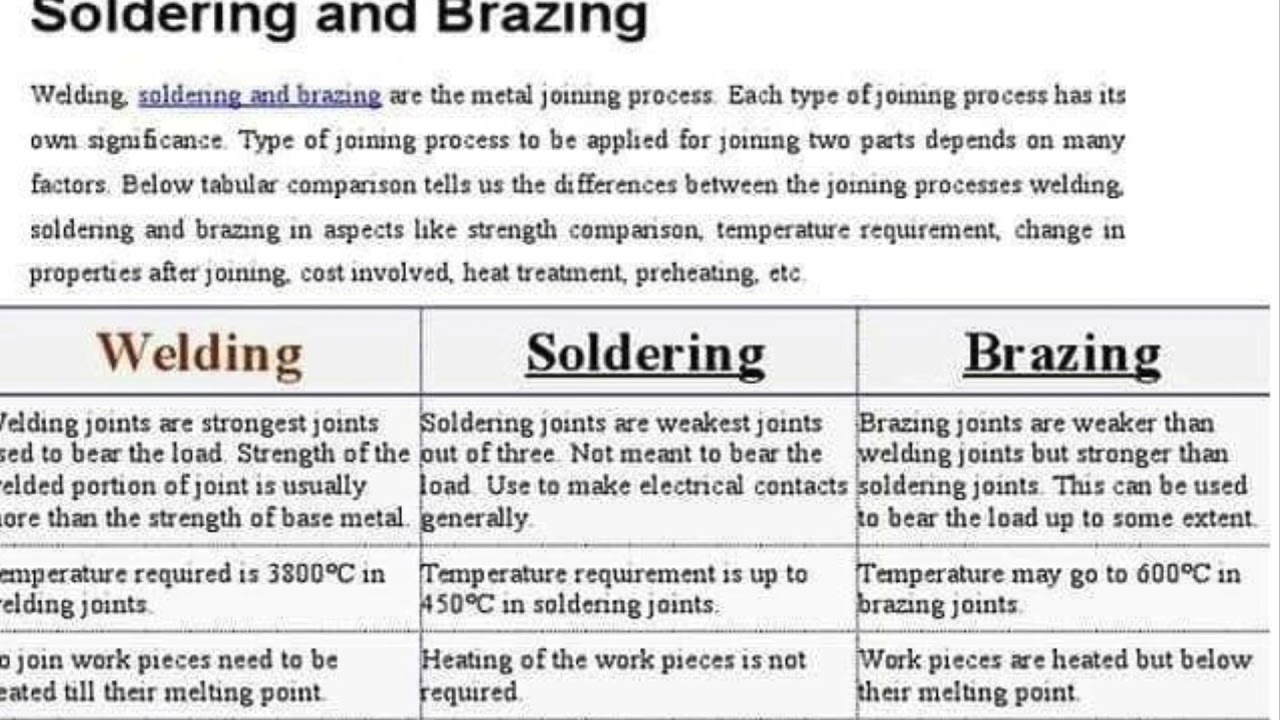

That temperature is defined to be 842ºF450ºC by the American Welding Society AWS but is often rounded to 840ºF. Solder has a liquidus above 450 C.

Difference Between Soldering And Brazing Difference Between

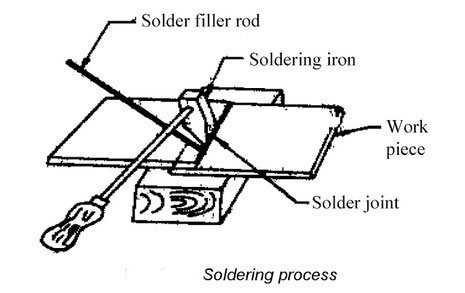

In soldering metal producers heat up the metal to be bonded but never soften them.

. These have a higher melting point of 500 to 650 degree centigrade. Soldering on the other hand makes use of a filler metal heated at temperatures lower than that. Brazing has the advantage of low power consumption low temperature and moderate weld strength compared to welding.

Preheating of base metal does not require in soldering. Brazing occurs at temperatures above 450C. Both the processes are quite the same except soldering uses filler alloys with melting temperatures below 450 C 840 F whereas brazing is to be carried out at temperatures above 450 C.

What differentiates soldering and brazing is the melting temperature of the filler metal. Silver solder utilizes an eraser flow of the solder compared to brazing. To sum up soldering has applications to join electronics parts to make electrical connections.

Brazing is quite costly. Soldering is most just like brazing since it uses capillary action to flow the metal into the joint untill it cools and hardens. Soldering and brazing both are mostly used in small industries.

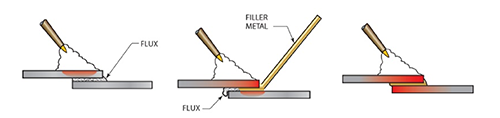

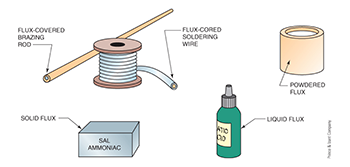

If soldering wasnt done properly the pieces wont conduct electricity properly. Just as in welding and brazing flux is used to clean metal surfaces so that the solder can flow over the pieces that will be joined. In fact the American Welding Society defines brazing as the process where the filler metal ie.

Above that temperature the process is brazing. Soldering occurs at temperatures around 400C. Some advantages of brazing and soldering as compared to other methods of joining include the following.

Each process has its advantages and disadvantages from a processing and application perspective. Dissimilar materials can be joined. According to the AWS definition Soldering is similar to brazing except that the filler metal used in Soldering has a liquidus lower than 840F 450C and below the solidus of the base metal.

Welding There are numerous types of welding processes including. Brazing is not easy and a very difficult for automation. Filler metal boiling point is above 450C.

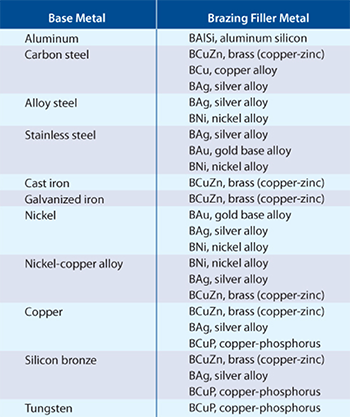

Arc Electron Beam Friction Laser Resistance. The filler metals may be of copper aluminum nickel silver. May be permanently or temporarily joined.

This means that when you want to join two metal pieces using silver solder you must clean and level off the ends so there is no light gap to the two ends to be soldered. The brazing produces stronger joints than soldering. Brazing is an adequate tool for very thin metal like aluminum.

Soldering and Brazing both are joining two or more similar and dissimilar metals. The flux used may be borax or boric acid. The main difference between the two is the temperature.

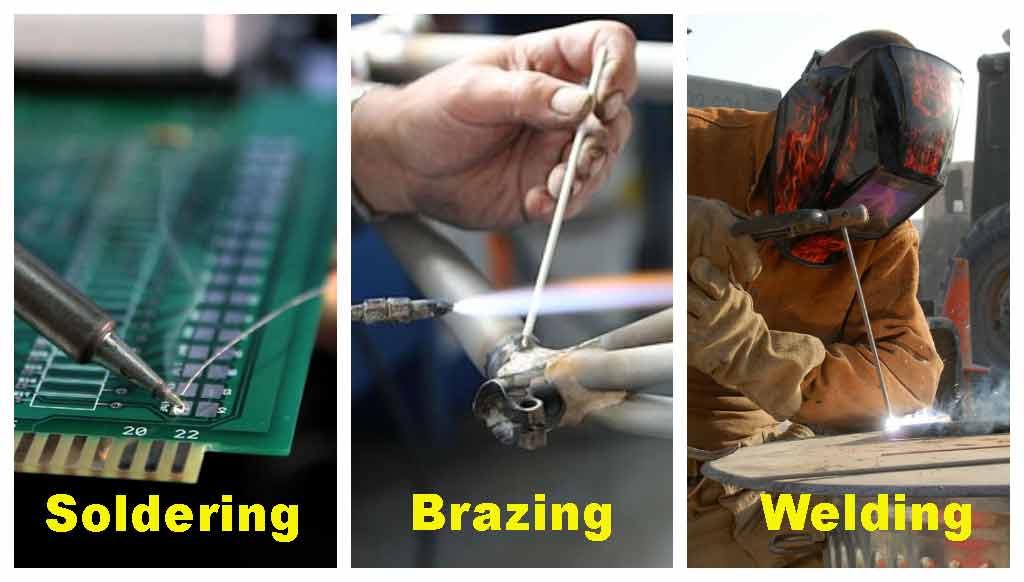

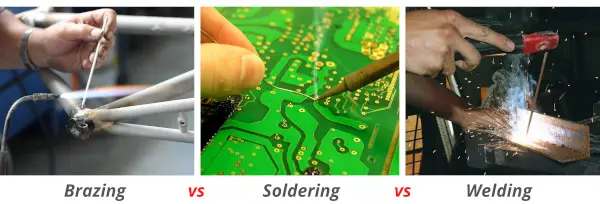

Unlike welding both soldering and brazing heat the filler metal sparing the base metal from melting and joins the two metals together. Although both soldering and brazing are two methods used to join metals and have similar definitions a difference can be observed between soldering and brazing. Now the difference is mainly the filler material composition and its melting point.

Advantages of Brazing and Soldering. The basic difference between soldering and brazing is the temperature necessary to melt the filler metal. Soldering takes place at a temperature below 840F 450C and brazing occurs at a temperature above 840F 450C.

However there are a number of differences between these two processes. Gap between metals to be joined When the gap between the metals parts is not a fine gap soldering can be used. Soldering is a semi-permanent fastener whereas brazing is a permanent fastener.

What is Difference Between Soldering and Brazing. Brazing is used to cover a fine gap between the metal parts to be joined. Heating of workpieces is not required.

10 rows The basic and main difference between soldering and brazing is that soldering is used to make a electrically strong joint between metals which can withstand with all electric loads and brazing is used to make a mechanical strong joint which can withstand with all mechanic loads and stresses. A soldered bond is not as strong as a welded or brazed one because it is not a mechanical connection. And we can use brazing to join dissimilar metals using a filler rod whereas welding joins similar metals at very high temperatures.

Key Difference Soldering vs Brazing. Whereas soldering accomplished at a temperature lower than 200C and brazing accomplished at temperature preceding 450C but under the risky or critical. Soldering is commonly used in plumbing works electronics arts and crafts engine repairs and metal works from flashing to jewelry.

Between the two brazing offers stronger joints compared to silver soldering. Like welding process but soldering and brazing joining strength is less as compared to welding. In soldering and brazing a metal alloy solder is melted and flows over the two metals to be joined connecting them together.

Soldering filler materials are alloys of lead and tin and normally have a melting point of 250 to 300 degree centigrade. Work pieces are heated but below their melting points. Both processes are used to join two or more metals together using a filler metal material which has a lower melting point than the joining metals.

Brazing filler materials are alloys of copper and tin zinc. Soldering is really a very easy and quick process. Soldering is a cheaper process.

Soldering Aforementioned brazing is kind of similar to brazing. The difference between brazing and soldering is a temperature of 450 degrees centigrade used in brazing which is much higher than soldering temperature. Soldering is used to link two or more metal things together through filler solder material and brazing distinct as the connection of two or more metal things to produce a combination of material.

So there is a common Difference between. For brazing you need higher temperatures to melt the filler. In welding metal producers melt the base metal.

As a low-temperature method of brazing Soldering can be considered the same. If the filler metal melts below 840ºF the process being performed is soldering.

The Difference Between Soldering And Brazing With Welding The Definitive Guide Cruxweld

The Difference Between Soldering And Brazing With Welding The Definitive Guide Cruxweld

Brazing Vs Soldering Vs Welding 9 Difference You Must Know

The Differences Between Welding Brazing And Soldering

The Differences Between Welding Brazing And Soldering

Brazing Vs Welding Vs Soldering What Is The Difference

Soldering Brazing And Braze Welding Ppt Download

Difference Between Soldering And Brazing Difference Between

Differences Between Soldering And Brazing Youtube

Soldering Vs Brazing Its Process Advantages Disadvantages

7 Main Differences Between Brazing And Soldering Simplified

Difference Between Soldering And Brazing Mech4study

The Differences Between Welding Brazing And Soldering

Difference Between Soldering And Brazing Difference Between

Soldering Vs Brazing Its Process Advantages Disadvantages

7 Main Differences Between Brazing And Soldering Simplified

The Difference Between Soldering Brazing And Welding Sra Resource Center

Difference Between Welding And Brazing And Soldering Youtube